Facts

High-quality products tailored directly to the customer are no problem thanks to our competencies in cutting, punching, sewing and laminating. We focus on working with high quality materials to create a high-quality end product. Combining the production techniques of cutting, punching, sewing and laminating allows us to carry out all the steps in product manufacture, from cutting to final assembly.

01

Precision

Cutting with the CNC cutter

To ensure optimal execution of production orders, raw materials are cut on our own high-precision CNC cutter. Material waste is kept to a minimum because specially created CAD nesting ensures maximum material yield. A wide variety of materials can be cut on the cutter, including:

- Textiles

- Cotton

- Leather and imitation leather

- Foams

- PVC films

- Rubber

- Cellulose and similar materials

02

FLAT PARTS

Punching

In addition to CNC cutting, raw materials can also be punched. Punching is a cutting process for producing flat parts from various materials by means of a punch press or by hitting a cutting tool with a hammer head. This way, raw materials can be shaped into the appropriate form for further processing. In our production, punched parts are further processed in the sewing and laminating area.

03

Optics and function

Sewing

Precise seams are required for the production of our products. Our CNC sewing machines produce high-precision stitches with an accuracy of up to 0.1 mm on interior trims. For example, decorative seams can be produced to enhance the appearance of a car’s interior as well as functional seams for tension straps in map pockets.

In addition to CNC sewing, sewing machines are also used for production. The following parts, among others, are produced there:

- Upholstery for the shipping industry

- Curtains for obscuring delivery vans

- Equipment for civil defense (emergency response)

04

Joining

Laminating

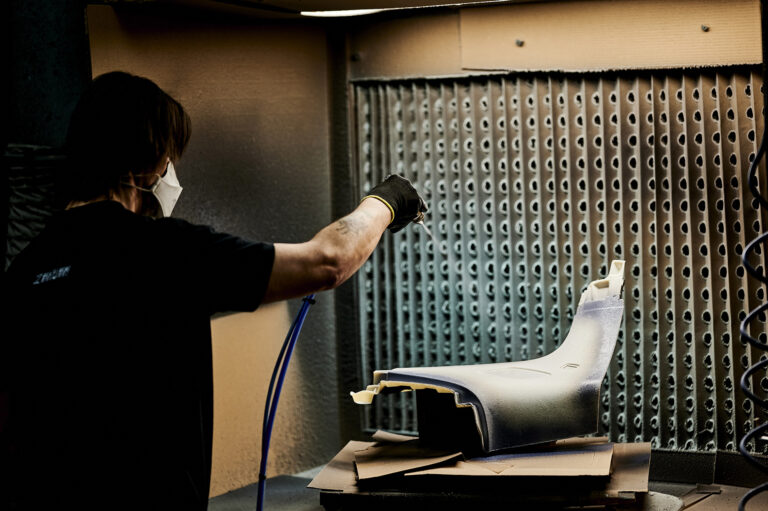

Lamination is the process of joining the same or different materials with the aid of a suitable laminating agent (adhesive). The laminating process can protect or refine materials or add favourable material properties.

The Zender Group uses lamination, among other things, for the production of car interiors. Here, visually appealing decorative materials are attached to a carrier material to create a high-quality, stable visual effect. Classic examples of laminated interior products include:

- Door panels

- Arm rests

- Parcel shelves

- Boot trim

- Gear knobs

Gallery